Precision that performs under pressure.

Intek is a precision aerospace and defense plastic parts manufacturer. These custom plastic components are built for the most demanding applications on earth — and beyond.

An ITAR-registered manufacturing partner, we understand the demands of mission-critical performance. Intek’s experienced team supports aerospace and defense programs with comprehensive plastic solutions. We work with manufacturers to refine parts for manufacturability, consistency and weight reduction — without compromising durability, safety or precision. From lightweight structural extrusions to impact-resistant molded components, every piece is built to perform reliably in extreme conditions.

Ask

Where Our Plastic Solutions Fit

- Aircraft interior trim and seals

- Cabin lighting diffusers and lens covers

- Wire and cable management channels

- Protective covers and housings

- UAV and drone enclosures

- Electrical insulation profiles and components

- Missile and launcher support parts

- Equipment handles, grips and brackets

- Lightweight panel connectors and clips

If it helps your windows and doors perform better, we can make it.

Engineered for mission-critical performance

When performance, safety and reliability are nonnegotiable, Intek delivers. Our materials and processes are chosen for stability, precision and compliance with aerospace and defense standards.

Count on:

- Lightweight, high-strength materials (PEEK, polycarbonate, nylon, ABS, PVC and more)

- Excellent chemical and temperature resistance

- Tight dimensional control and repeatability

- EMI/RFI shielding and electrical insulation options

- UV, flame and impact resistance

- Traceability and quality assurance documentation

Your complete manufacturing partner

Intek provides everything you need under one roof — from design-for-manufacturing and additive manufacturing to high-precision production, assembly and inventory management.

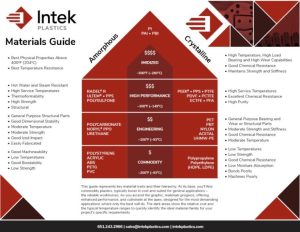

Injection Molding Materials Guide

Resource

Selecting the best material for your molded part doesn’t have to be complicated. This guide breaks down the plastic options that deliver the performance, cost efficiency and consistency your design needs — so you can make informed decisions with ease.

Extrusion Materials Guide

Resource

This guide walks you through the most common extrusion plastics, helping you find the ideal balance of strength, flexibility and aesthetics for your product. Let’s find what performs best for your next innovation. For complex performance needs, we specialize in co-extrusions, tri-extrusions, and quad-extrusions — combining materials to deliver the perfect balance.

Here’s how we support you at every step:

High-performance aerospace and defense plastic solutions refined for strength, dimensional stability and low weight.

Complex components produced with materials engineered for durability and temperature performance.

Prototyping

Rapid prototypes that help you evaluate form, fit and function — accelerating validation and qualification cycles.

Secondary processes

Cutting, drilling, punching, inline pad printing and adhesive application, all performed in-house for repeatable quality.

Assembly and kitting

Subassemblies and multi-part builds that simplify your manufacturing flow and reduce lead times.

You get a single, reliable partner who understands your business — not just your parts.

Mission-ready collaboration

We know every component plays a role in a larger mission. That’s why our team works closely with yours to refine part designs for manufacturability — reducing cycle time, minimizing waste and improving overall performance.

From your first prototype to full production, you can expect transparent communication, reliable quality and components that meet your strictest specifications.