Custom Plastic Extrusion Manufacturer

Custom plastic extrusion profiles take shape through smart collaboration. You bring the design, and Intek Plastics helps refine it for manufacturability to save you time, reduce costs and improve long-term performance. From simple shapes to complex multi-material profiles, we work with your team to turn your concept into a reliable, production-ready solution.

Backed by lean manufacturing, continuous improvement and decades of extrusion expertise, we focus on creating value together. Our full range of services, including engineering support, fabrication, assembly, inventory management and more, help ensure your profiles and assemblies are produced efficiently, consistently and exactly the way you need it.

Ask

Where Our Plastic Solutions Fit

- Door and window profiles

- Tubes and multi-channel profiles

- Weatherstripping and sealing components

- Trim, edge guards and molding profiles

- Structural and functional components

- Specialty profiles for data center, industrial and other applications

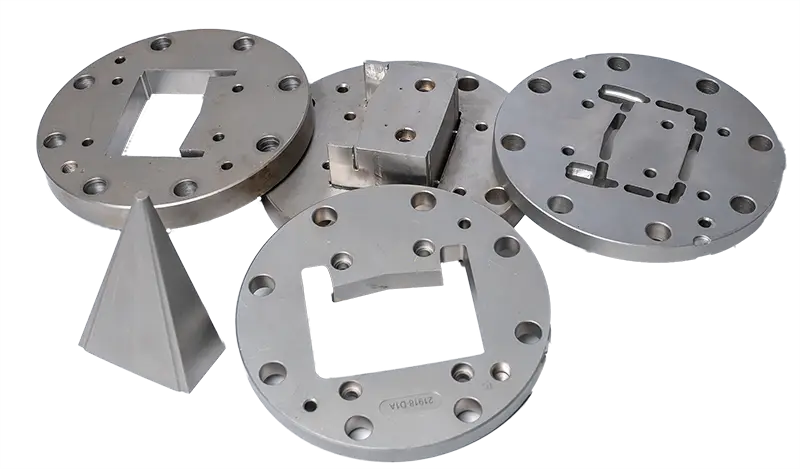

In-House Tooling Built for Quality

Your extrusion is only as good as the tooling behind it. Our in-house tooling team designs, builds and refines dies with precision, ensuring tight tolerances, clean finishes and optimized material flow. We focus on durability, repeatability and efficient startup, helping you minimize scrap, reduce downtime and maintain consistent quality across every run.

Extrusion is only the beginning. We offer a full suite of value-added services to help deliver a part that’s closer to finished form, reducing your labor, cost and assembly steps.

- Precision cutting and fabrication

- Punching, routing and drilling

- Heat bending and forming

- Adhesive application and assembly

- Packaging, kitting and custom labeling

The result: parts that arrive ready to go, right when you need them.

Why Choose Intek for Custom Plastic Extrusion Profiles?

- Collaborative approach from start to finish:

We listen first, ensuring your extrusion is built around your specifications. - Innovative thinking backed by proven expertise:

Our team combines innovation with decades of practical knowledge. - Material and tooling leadership:

We design precision tooling and help select the right materials to enhance performance and durability. - Reliable, repeatable quality:

Our advanced extrusion lines and rigorous inspection processes deliver consistent results across every run. - End-to-end support:

With DFM, prototyping, value-added services and inventory programs, we simplify your supply chain.

Extrusion Materials Guide

Resource

This guide walks you through the most common extrusion plastics, helping you find the ideal balance of strength, flexibility and aesthetics for your product. Let’s find what performs best for your next innovation. For complex performance needs, we specialize in co-extrusions, tri-extrusions, and quad-extrusions — combining materials to deliver the perfect balance.

Secondary Operations

Where Plastic Magic Gets Finished

Intek Plastics goes beyond molding and extruding to make sure your plastic parts are truly production ready. From pad printing and laser marking to mechanical assembly and kitting, our in-house secondary operations turn components into complete, market-ready solutions. Combined with our integrated inventory management and just-in-time delivery, we keep your production line humming.

Here’s how we support you at every step:

High-performance parts refined for strength, dimensional stability and low weight. Our design-for-manufacturing expertise ensures your designs meet exacting tolerances and efficiency goals.

Complex, tight-tolerance components produced with materials engineered for impact resistance, chemical stability and temperature performance.

Rapid prototypes that help you evaluate form, fit and function — accelerating validation and qualification cycles.

Cutting, drilling, punching, inline pad printing and adhesive application — all performed in-house for repeatable quality.

Subassemblies and multi-part builds that simplify your manufacturing flow and reduce lead times.