In-House Tooling and Global Supplier Network

Quality products start with quality tooling. Intek’s in-house tool and die team uses advanced advanced software, CNC machining and the latest EDM technology to build high-performance tools for custom plastic extrusion and injection molding. We work closely with your team to shape your vision into manufacturable, production-ready components that meet your performance, aesthetic and cost goals.

With full in-house and sourced tooling capabilities, we provide design flexibility, shorter lead times and tighter process control, all of which help reduce your time to market and improve overall part quality.

Ask

Tooling Expertise for Extrusion and Injection Molding

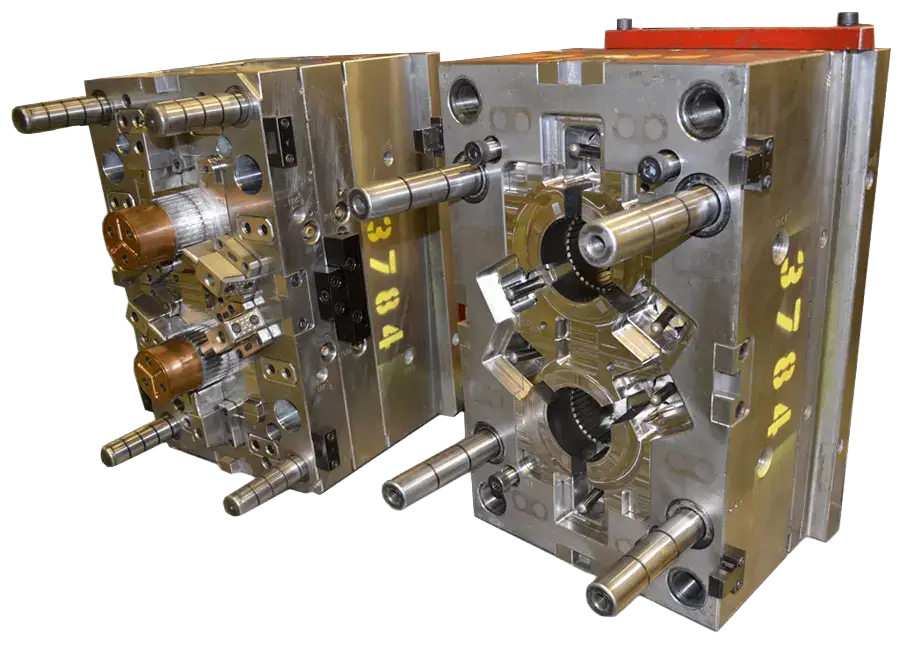

Injection Molding Tooling Capabilities

- Single- and multi-cavity molds

- Hot-runner and cold-runner systems

- Insert and overmold tooling

- Mold modifications and repairs

- Prototype to production-intent tooling

- Seamless tool transfer

Whether you need prototype tooling or complex production-ready dies and molds, we engineer solutions that support consistent performance and long-term durability.

Extrusion Tooling Capabilities

- Custom profile dies

- Multi-material co-extrusion and tri-extrusion tooling

- Vacuum calibration tooling

- Sizing fixtures

- Sample and prototype dies

Flexible, High-Quality Tooling Solutions

We offer a high-quality, in-house tool shop that delivers fast turnaround and precise tooling for extrusion and injection molding. Our team designs, programs and builds tools using advanced systems and state-of-the-art equipment.

When projects require outsourced tooling, we tap into a trusted global supplier network, including domestic and overseas partners, to provide cost-effective options without sacrificing quality.

If you have existing tooling, Intek provides smooth tooling transfer support to help improve part quality, consistency and lead times.

Sourced Tooling When Needed

While we manufacture most tooling in-house, some projects demand specific capabilities, cost advantages or timelines that benefit from strategic sourcing. We partners with trusted domestic and international suppliers to provide:

- Competitive pricing

- Specialized toolmaking capabilities

- Scalable tool builds for large programs

- Fast turnaround on select tool types

Every sourced tool is reviewed, tested and qualified by our engineering and quality teams.