Turn your bright ideas into reality.

Let’s bring it to life — faster, smarter and better. Intek Plastics specialize in custom extrusion, injection molding and rapid prototyping to help your lighting creations go from concept to reality without the guesswork. With precision design for manufacturing, cutting-edge materials and a whole lot of innovation, we don’t just make lighting components — we craft solutions built for performance, durability and sustainability.

When you work with Intek, you get high-quality plastic lighting components and a team that’s as invested in your success as you are. Whether you need lenses, diffusers, reflectors or housings, we tailor every solution to your exact specifications.

Ask

Plastic Extruded Lenses, Diffusers and Reflectors

- Acrylic and polycarbonate lenses and reflectors

- Co-extrusions, tri-extrusions, and quad-extrusions

- Linear diffusers and optics

- Clear, frosted and diffuse options

- IntekSmart bioplastic composite profiles, lenses and diffusers

Your complete manufacturing partner

We don’t just create components — we develop solutions that enhance lighting performance, efficiency, sustainability and aesthetics. We are committed to collaborating with you to revolutionize your lighting products with cutting-edge plastic solutions. Our skilled engineers work closely with you to recommend the perfect materials and provide engineering assistance that ensures your custom lighting profiles and diffuser lenses conform to your precise standards. Contact us to learn more.

You get a single, reliable partner who understands your business — not just your parts.

A Bright Idea: Working With Intek Plastics

When it comes to custom lighting diffusers, lenses and housings, Intek is your go-to source of high-quality plastics, expert engineers and intelligent lighting extrusions. Our dedication to the craft of processing highly engineered polymers, including acrylics and polycarbonates, has given us a comprehensive understanding of the characteristics of each and the applications for which each is best suited. Intek can inherently recognize which plastic materials will deliver the best performance for your application.

Collaborative Design

Whether it’s for industrial, commercial, architectural or area lighting applications, we are committed to delivering the highest quality and performance in linear profile extrusions for the lighting market. We’re driven by the idea that the best work comes from craftsmanship, communication, and great teamwork. From your very first conversation through delivery of your final order, we make it our priority to provide best-in-class customer service throughout the entire lighting extrusion process. Contact us to learn more.

Here’s how we support you at every step:

Plastic extrusion

Custom electronics profiles, including complex multi-material extrusions, refined for insulation, durability and precision fit.

Plastic injection molding

Tight-tolerance components molded with materials that meet electrical, flame-retardant and heat-resistant requirements.

Prototyping

Rapid prototypes that allow you to test fit, finish and thermal performance before full production.

Secondary processes

Cutting, drilling, punching, inline pad printing and adhesive application — all handled in-house for consistent quality and faster turnaround.

Assembly and kitting

Multi-part subassemblies and components built for seamless integration into your manufacturing line.

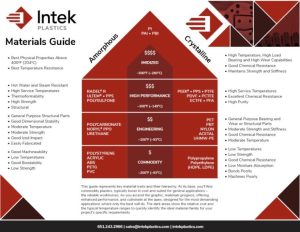

Injection Molding Materials Guide

Resource

Selecting the best material for your molded part doesn’t have to be complicated. This guide breaks down the plastic options that deliver the performance, cost efficiency and consistency your design needs — so you can make informed decisions with ease.

Extrusion Materials Guide

Resource

This guide walks you through the most common extrusion plastics, helping you find the ideal balance of strength, flexibility and aesthetics for your product. Let’s find what performs best for your next innovation. For complex performance needs, we specialize in co-extrusions, tri-extrusions, and quad-extrusions — combining materials to deliver the perfect balance.