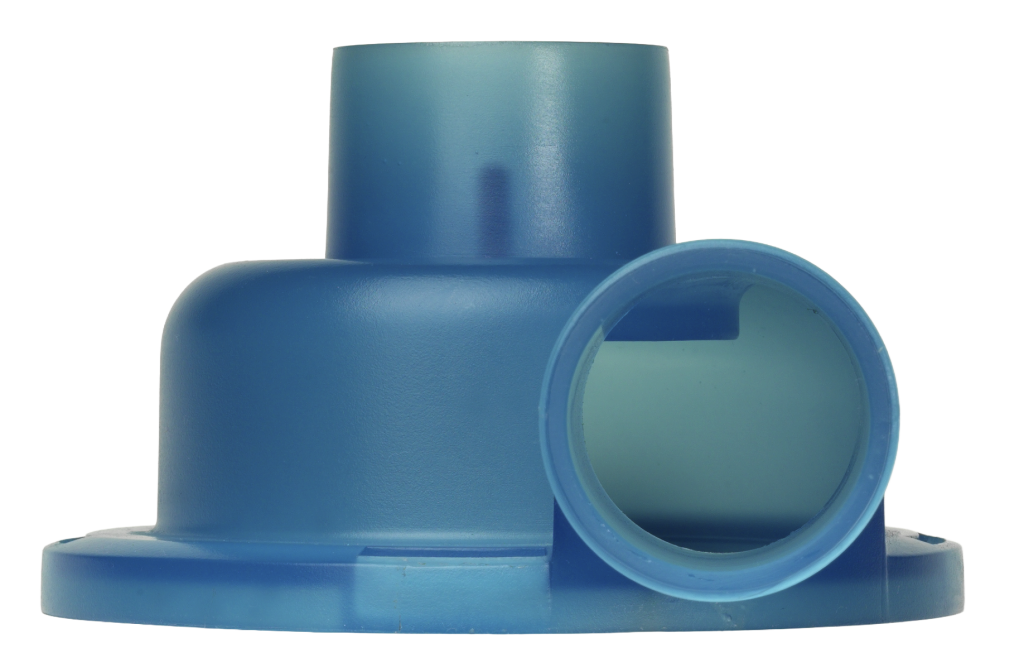

High-Quality Urethane Casting for Low-Volume Production

Cast urethane parts are an ideal choice when you need high-quality components without the cost or lead time of full production tooling. Intek’s urethane casting gives you the flexibility to validate designs, create functional models or build short-run parts that look and perform like injection-molded components — at a fraction of the investment.

With customizable materials, color options and performance characteristics, we help you choose the right urethane solution for your application. Our team partners with you throughout the process, ensuring your cast parts meet your specifications while saving you time and reducing your upfront costs.

Ask

Why Cast Urethane Works for Low-Volume Production

Urethane casting fills the gap between 3D printing and injection molding. It provides production-quality looks and performance with minimal tooling cost. Perfect when you need:

- Short runs without long lead times

- High-detail components

- Flexible or rigid materials

- Color-matched or custom finishes

- Rapid product iteration

This makes it a powerful option for teams refining a design, launching an early product release, or testing the market before moving to full-scale manufacturing.

Cast Urethane Capabilities

Our capabilities support a wide range of product needs and performance levels:

- Multi-shot cast parts

- Custom color matching

- Insert-molded urethane models

- Decorative secondary operations and graphics

- Any Shore A durometer or Shore D hardness

- Medical-grade and FDA-compliant options

- Light pipe and optical clarity

- Impact-resistant formulations

- UL flame-rated materials

- Multi-level transparency options

Whether you need soft-touch components, rigid housings, clear lenses or flexible gaskets, we can replicate the feel and function of your final injection-molded part.

Applications for Cast Urethane

- Low-volume and bridge production

- Engineering validation parts

- Assembly fit checks

- Early-stage product testing

- Marketing and demo models

- Functional trade show prototypes

Your complete manufacturing partner

Speed and functionality matter. Whatever your project demands, we have in-house technology and expertise to make it happen. Your next breakthrough is just a print away. Let’s prototype the future. Request a quote today.

You get a single, reliable partner who understands your business — not just your parts.

High-performance plastic solutions refined for strength, dimensional stability and low weight.

Complex components produced with materials engineered for durability and temperature performance.

Prototyping

Rapid prototypes that help you evaluate form, fit and function — accelerating validation and qualification cycles.

Secondary processes

Cutting, drilling, punching, inline pad printing and adhesive application, all performed in-house for repeatable quality.

Assembly and kitting

Subassemblies and multi-part builds that simplify your manufacturing flow and reduce lead times.

Inventory control and just-in-time delivery

Reliable supply chain programs that ensure consistent availability.

Mission-ready collaboration

We know every component plays a role in a larger mission. That’s why our team works closely with yours to refine part designs for manufacturability — reducing cycle time, minimizing waste and improving overall performance.

From your first prototype to full production, you can expect transparent communication, reliable quality and components that meet your strictest specifications.