Plastic Multi-Material and Co-Extrusion Profiles

Custom plastic co-extrusions give you more freedom to innovate. As a trusted custom extruder, we deliver high-quality materials, skilled engineers and future-forward technology to produce multi-material plastic profiles that elevate performance, appearance and efficiency.

Our long-standing commitment to processing highly engineered polymers gives us a deep understanding of how materials behave and how to combine them to take your parts to the next level.

Ask

Plastic Co-Extrusion and Multi-Material Profiles

Multi-material and co-extrusion is the process of extruding two or more thermoplastic materials through a single die with multiple openings. This allows each material to contribute its own strengths within one unified profile.

Common co-extrusion materials include:

- Polyvinyl chloride (PVC)

- Acrylonitrile butadiene styrene (ABS)

- Thermoplastic elastomers (TPE)

- High-density polyethylene (HDPE)

We can combine two or more raw materials into one profile, creating bonded structures with different hardness levels, colors or performance characteristics. For added functionality, Intek also offers tri-extrusions and quad-extrusions that unlock new design possibilities.

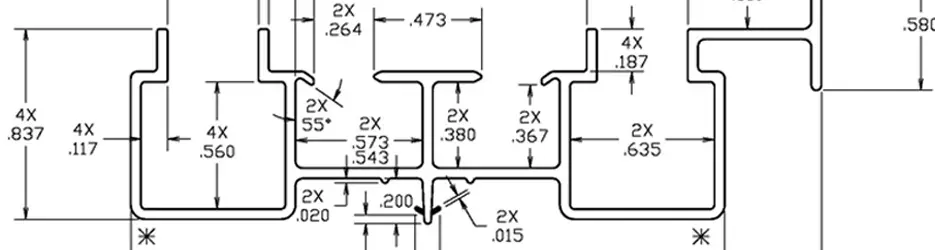

Design for Manufacturability (DFM)

We believe the best products come from a strong partnership. Our engineers work with your team early in the process to optimize geometry, wall thickness, assembly fit and manufacturability. Through modeling, simulation and rapid prototyping, we solve challenges upfront — reducing costly redesigns and speeding up time-to-market.

Advantages of Plastic Co-Extrusions From Intek Plastics

- Cost Efficiency: Co-extrusion delivers advanced performance at a lower total cost.

- Improved Appearance: Rigid and flexible plastics create durable, scratch-resistant color and finishes without the need for painting.

- Material Optimization: Combining materials can eliminate assembly steps or reduce the number of components required.

- Advanced Tooling Capabilities: We incorporate design-for-manufacturing (DFM) insights to support even the most complex profiles.

If you’re not getting this level of support from your current custom plastic extruder, it may be time to partner with a team that brings expertise, innovation and true collaboration to every project.

Whether you’re considering replacing an aluminum part with a plastic profile or exploring how a co-extruded solution can better support your design goals, Intek Plastics has the expertise to guide you through every step.

We have supported hundreds of customers, many new to co-extrusion, by offering clear communication, hands-on engineering support and a structured development process that leads to successful outcomes.

Here is what you can expect when partnering with Intek:

- Project Engineering Review

- Fabrication Recommendations

- Die Building

- Finished Part Analysis

- Production Planning

- Value-Added Serices

You get a single, reliable partner who understands your business — not just your parts.

Extrusion Materials Guide

Resource

This guide walks you through the most common extrusion plastics, helping you find the ideal balance of strength, flexibility and aesthetics for your product. Let’s find what performs best for your next innovation. For complex performance needs, we specialize in co-extrusions, tri-extrusions, and quad-extrusions — combining materials to deliver the perfect balance.

Secondary Operations

Where Plastic Magic Gets Finished

Intek Plastics goes beyond molding and extruding to make sure your plastic parts are truly production ready. From pad printing and laser marking to mechanical assembly and kitting, our in-house secondary operations turn components into complete, market-ready solutions. Combined with our integrated inventory management and just-in-time delivery, we keep your production line humming.