Bringing performance, precision and polish to everyday products.

From concept to production, custom plastic component manufacturing for consumer products is where Intek helps ideas take shape. We partner with brands to turn great designs into reliable, manufacturable realities — balancing form, function and efficiency every step of the way.

From appliance trims and handles to sporting goods, furniture components and more, our team partners with you to refine visual appeal and performance that helps products sell. Whether you’re launching a new product or improving an existing one, we’ll help you achieve consistent quality, lower production costs and faster time to market.

Ask

Where Our Plastic Solutions Fit

- Appliance handles, trim and decorative profiles

- Seals, gaskets and edge protection

- Furniture and fixture components

- Sporting goods and leisure equipment

- Retail product components

- Home and garden product parts

- Consumer electronic housings and accessories

If it needs to look great, perform well and be produced efficiently, we can make it happen.

ouR get a single, dependable partner who understands your products, your brand and your goals.

Designed for manufacturability and market success

We know your customers notice the details — how something looks, feels and performs. Our team refines each part for efficient production, visual appeal and lasting durability.

Count on:

- Tight, consistent tolerances for perfect fit and finish

- Color matching and surface finishing options

- Durable, lightweight materials for daily use

- Scalable production increasing demand

- Rapid turnaround for market responsiveness

Collaboration that delivers results

Intek’s collaborative process helps product developers and brand engineers move from concept to completion with confidence. Our material experts guide you in selecting the right polymers for performance, texture and aesthetics — while our design-for-manufacturing approach ensures every part is efficient to produce and beautiful to use.

From your first prototype through full-scale production, you can count on us for open communication, reliable quality and components that make your brand stand out.

Your complete manufacturing partner

Intek brings material expertise, scalability and precision to every project. You’ll find everything you need under one roof — from design-for-manufacturing refinement and rapid prototyping to extrusion, injection molding, assembly and inventory control.

Here’s how we support you at every step:

Plastic injection molding

Durable, high-precision parts that meet demanding design and aesthetic standards.

Prototyping

Rapid prototypes that help you validate color, fit, finish and function before production.

Secondary processes

Cutting, drilling, punching, inline pad printing and adhesive application, all done in-house

Assembly and kitting

Subassemblies that simplify your production and help your products ship ready to use.

Injection Molding Materials Guide

Resource

Selecting the best material for your molded part doesn’t have to be complicated. This guide breaks down the plastic options that deliver the performance, cost efficiency and consistency your design needs — so you can make informed decisions with ease.

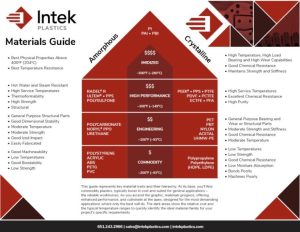

Extrusion Materials Guide

Resource

This guide walks you through the most common extrusion plastics, helping you find the ideal balance of strength, flexibility and aesthetics for your product. Let’s find what performs best for your next innovation. For complex performance needs, we specialize in co-extrusions, tri-extrusions, and quad-extrusions — combining materials to deliver the perfect balance.