Custom data center plastic components, tailored to your needs

Intek specializes in delivering precision custom data center plastic extrusions and plastic injection molded parts. Our dedicated team works closely with your engineers to create sustainable and efficient plastic extruded components that meet your specifications and are designed with the future in mind.

We offer a wide range of material options, including bio-composite plastics, acrylonitrile butadiene styrene (ABS), polyvinyl chloride (PVC), and polyethylene (PE). We can source nearly any plastic extrusion material required for specific performance criteria. For projects that demand a combination of material properties, Intek provides expert co- and tri-extrusions.

Ask

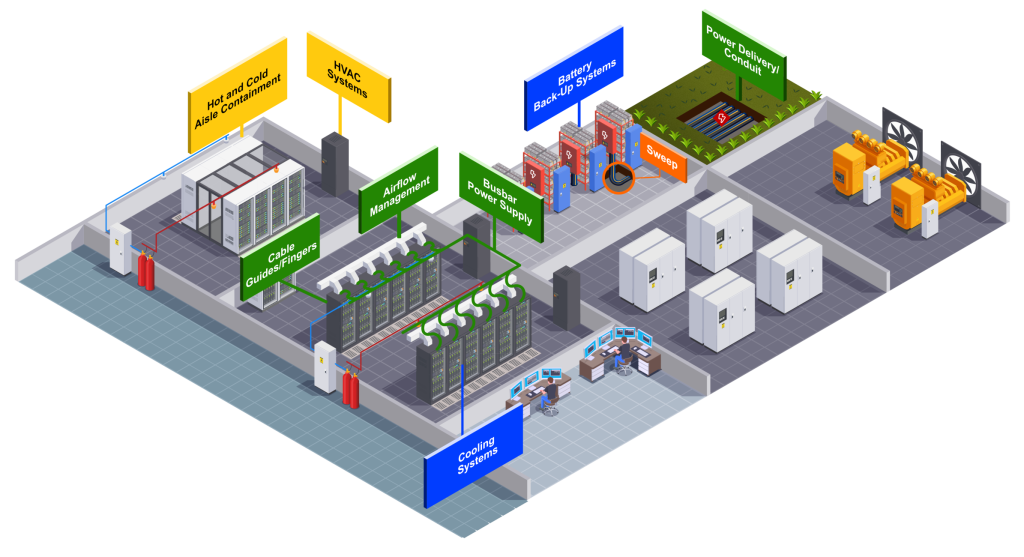

Key Applications for Data Centers:

- Airflow management

- Battery back-up systems

- Busbar insulators

- Cable and wire management

- Extruded PVC tubing

- Extrusions to maximize airflow

- Gasketing

- Hot and cold aisle containment

- Power delivery/conduit

- Linear plastic enclosures

- Powerbars

How plastics are powering data center innovation

Free White Paper

Plastics are rapidly becoming the material of choice for data center innovation, offering compelling advantages over traditional materials like metal, glass and rubber. Our white paper dives into the unique benefits engineered plastics bring, from their exceptional balance of strength, weight and flexibility to their ability to be precisely tailored for thermal, mechanical and chemical performance.

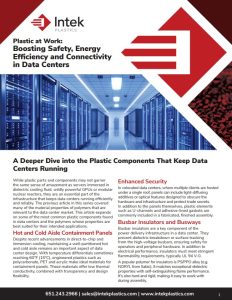

Plastics Components that Keep Data Centers Running

Free White Paper

This article expands on some of the most common plastic components found in data centers and the polymers whose properties are best suited for their intended applications, including:

- Hot and cold aisle containment panels

- Busbar insultors and busways

- Optimized conduit and pipes

- Durable cable management

- Linear enclosures

Custom Data Center Plastic Extrusions and Injection Molding

Sell Sheet

Intek specializes in custom plastic extrusions and injection molding that keep those server farms humming. We work with your engineers to create sustainable and efficient components because even servers deserve a little TLC (and a lot of airflow).

Many Material Options to Meet Your Requirements for:

- High dielectric strength

- Durability

- Impact resistance

- Chemical resistance

- Flame resistance

- Thermal requirements

- Energy efficiency

- ASTM-E-84 Class A compliance

- Light weight material options

Intek is your innovation partner. Our experience in collaborative design, material selection and supply chain efficiency, ensures that you’ll get products that fit seamlessly into your manufacturing stream.

Here’s how we support you at every step:

High-performance plastic solutions refined for strength, dimensional stability and low weight.

Complex components produced with materials engineered for durability and temperature performance.

Prototyping

Rapid prototypes that help you evaluate form, fit and function — accelerating validation and qualification cycles.

Secondary processes

Cutting, drilling, punching, inline pad printing and adhesive application, all performed in-house for repeatable quality.

Assembly and kitting

Subassemblies and multi-part builds that simplify your manufacturing flow and reduce lead times.

Inventory control and just-in-time delivery

Reliable supply chain programs that ensure consistent availability.