Fenestration. Perfection.

Intek brings performance and precision to fenestration plastic extrusions and injection-molding projects. Components we create for window and door manufacturers, include weatherstripping, extruded plastic profiles, compression gaskets, thermal breaks, jambliners and more.

For nearly four decades, we’ve helped leading window and door manufacturers redefine products that seal tighter, perform longer and look better. Whether you need a complex extrusion, a precision-molded component or a complete assembly, we’ll help you make it happen — on time and on spec.

Ask

Where Our Plastic Solutions Fit

- Window and door weatherstripping

- Continuous seal weatherstripping

- Thermal breaks and spacers

- Plastic door sweeps

- Window jambliners

- Compression gaskets

- Co-, tri- and quad-extrusions

- Injection-molded end caps, corner keys and inserts

If it helps your windows and doors perform better, we can make it.

Your complete manufacturing partner

You shouldn’t need many suppliers to finish one project. You’ll find everything you need in one place — from design for manufacturing efficiencies and precision production to inventory management and swift delivery.

You get a single, reliable partner who understands your business — not just your parts.

Performance that shows in every detail

Your customers notice every detail — the fit, the finish, the feel. That’s why we manufacture each part to perform beautifully and last for years.

Count on:

- Excellent thermal and energy performance

- UV and weather resistance

- Tight, consistent seals

- Custom color and finish matching

- Seamless integration of extruded and molded components

- Streamlined production with less waste

A Clear View, Working With Intek Plastics

When your window and door project demands eye-catching aesthetics, superior thermal performance and long-lasting weatherability, Intek opens the door to exceptional fenestration extrusions and injection molding.

From the first conversation to final delivery, you’ll always have a clear view and an open line with Intek. Our promise: real people, honest communication and components that perform exactly as promised.

Our collaborative approach ensures your products meet exacting standards. We’ll support you from design to delivery — offering prototype development, material recommendations and dependable manufacturing that scales with your production.

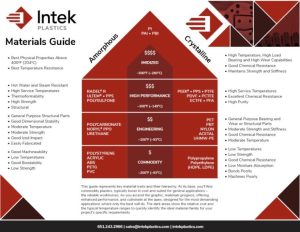

Extrusion Materials Guide

Resource

This guide walks you through the most common extrusion plastics, helping you find the ideal balance of strength, flexibility and aesthetics for your product. Let’s find what performs best for your next innovation. For complex performance needs, we specialize in co-extrusions, tri-extrusions, and quad-extrusions — combining materials to deliver the perfect balance.

Injection Molding Materials Guide

Resource

Selecting the best material for your molded part doesn’t have to be complicated. This guide breaks down the plastic options that deliver the performance, cost efficiency and consistency your design needs — so you can make informed decisions with ease.

Here’s how we support you at every step:

Plastic extrusion

Custom fenestration profiles optimized for performance, aesthetics and long-term durability. Our design-for-manufacturing expertise ensures your designs are enhanced for consistent production.

Plastic injection molding

High-precision, repeatable parts that integrate seamlessly with your extrusion components for complete window and door systems.

Prototyping

Fast, accurate prototypes that help you validate form, fit and function before full production — saving time, material and cost.

Secondary processes

Cutting, drilling, punching, inline pad printing and adhesive application — all handled in-house for consistent quality and faster turnaround.

Assembly and kitting

Ready-to-install subassemblies that simplify your production process and reduce labor time.

Inventory control and just-in-time delivery

Managed inventory programs that lower storage costs and keep your business running smoothly.