Specialty Services Enhance Your PRoducts

Intek Plastics’ specialty services are designed to help you move from concept to finished component with greater speed, efficiency and confidence. Whether you need secondary operations, assembly or tailored inventory management, we work as an extension of your team — helping you reduce costs, shorten lead times and simplify your workflow.

Our value-added capabilities complement our core strengths in extrusion, injection molding and additive manufacturing. The result: a fully integrated manufacturing process that delivers the quality, accuracy and consistency your program requires.

Ask

Services That Help You Build Better Products, Faster

When precision matters and timelines are tight, our services help streamline your workflow. We focus on efficiency, consistency and solutions that improve every part of your build.

- A collaborative, customer-first approach

- End-to-end manufacturing support

- Reliable quality and repeatability

- Faster timelines and reduced total cost

- Flexibility for any production level

Value-Added Services That Streamline Production and Strengthen Your Supply Chain

Precision Cutting

Heat Staking

Marking and Decorating

Tape Application

Custom Packaging

Returnable Packaging

Inventory Management

Sequenced Deliveries

Your complete manufacturing partner

Intek provides everything you need under one roof — from design-for-manufacturing and additive manufacturing to high-precision production, assembly and inventory management.

Injection Molding Materials Guide

Resource

Selecting the best material for your molded part doesn’t have to be complicated. This guide breaks down the plastic options that deliver the performance, cost efficiency and consistency your design needs — so you can make informed decisions with ease.

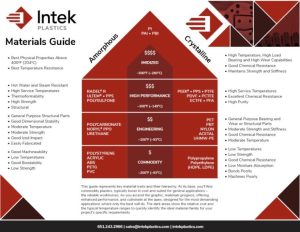

Extrusion Materials Guide

Resource

This guide walks you through the most common extrusion plastics, helping you find the ideal balance of strength, flexibility and aesthetics for your product. Let’s find what performs best for your next innovation. For complex performance needs, we specialize in co-extrusions, tri-extrusions, and quad-extrusions — combining materials to deliver the perfect balance.

Mission-ready collaboration

We know every component plays a role in a larger mission. That’s why our team works closely with yours to refine part designs for manufacturability — reducing cycle time, minimizing waste and improving overall performance.

From your first prototype to full production, you can expect transparent communication, reliable quality and components that meet your strictest specifications.