Stereolithography (SLA)

For Concept Models, Rapid Prototyping, Master Patterns And Low Volume Manufacturing

Ask

Get Fast Answers and Results

You can depend on us for:

- SAME DAY PRICING – We are standing by to review your product and let you know exactly what its going to cost

- LIVE ENGINEERING SUPPORT – We are standing by to answer any of your questions so you can make the best decision and move your project along quickly.

- FAST DELIVERY – Recieve your parts within 24 to 48 hours anywhere in the United States (*Same day delivery in the Twin Cities Metro Area)

Partner With Pros

Leverage an experienced engineering team that you can trust to manage everything from a small one-off part to high and low volume manufacturing to overall project management.

Send us your CAD file and our staff helps identify the best process and material for your project.

We use one of our industrial grade 3D Printers to create your parts. We leverage the following technologies: Stereolithography (SLA), Fused Deposition Modeling (FDM), and Selective Laser Sintering (SLS)

You Get It

When your parts are complete we package them up and rush them to you.

Mission-ready collaboration

We know every component plays a role in a larger mission. That’s why our team works closely with yours to refine part designs for manufacturability — reducing cycle time, minimizing waste and improving overall performance.

From your first prototype to full production, you can expect transparent communication, reliable quality and components that meet your strictest specifications.

additive manufacturing processes

Available Materials:

- Accura Xtreme White 200

- Acurra ClearVue

- Accura 25

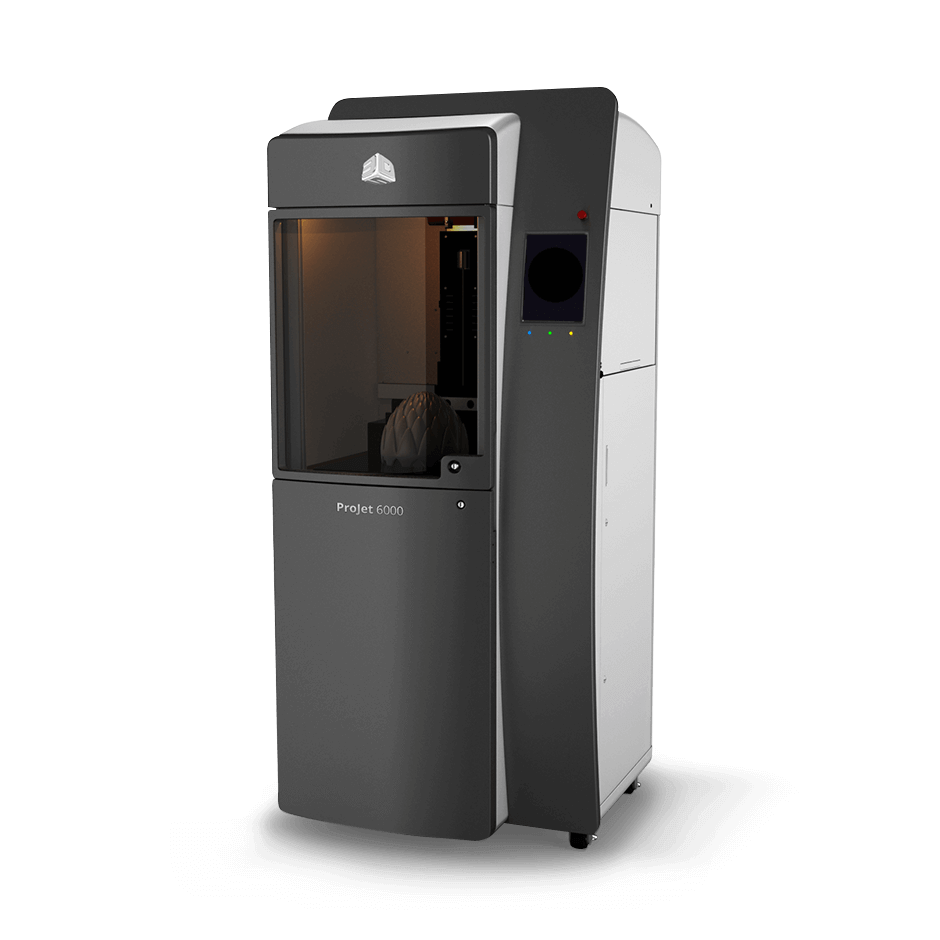

3D Systems ProJet 6000 HD

Stereolithography (SLA)

Description:

Stereolithography is an additive manufacturing process that works by focusing an ultraviolet (UV) laser on to a vat of photopolymer resin.

Applications:

- Design verification

- Complex assemblies

- Mass customization of product (orthodontic, dental)

- Assembly jigs and fixtures

Build Size:

10 x 10 x 10 inches (250 x 250 x 250 mm)

Precision:

+/- 0.004” or +/- 0.001” per inch, whichever is greater

Available Materials:

- Accura Xtreme White 200

- Acurra ClearVue

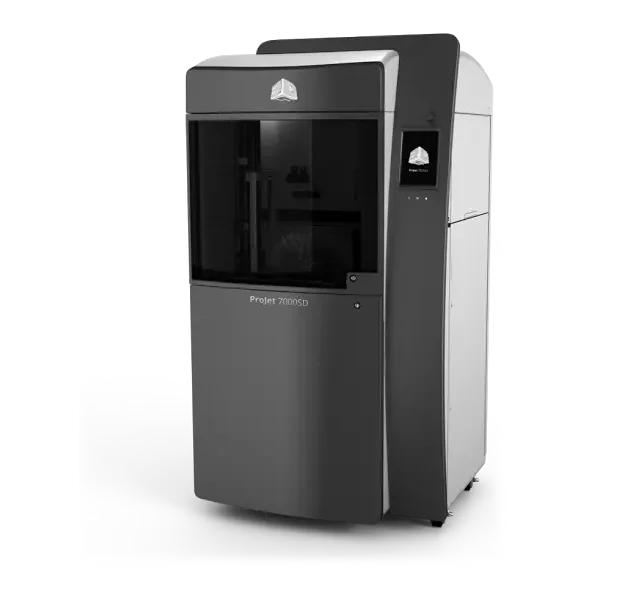

3D Systems ProJet 7000 HD

Stereolithography (SLA)

- Description:

Stereolithography is an additive manufacturing process that works by focusing an ultraviolet (UV) laser on to a vat of photopolymer resin. Same perks and process as the Projet 6000 but with a larger build size.

Applications:

- Design verification

- Complex assemblies

- Mass customization of product (orthodontic, dental)

- Assembly jigs and fixtures

Build Size:

15 x 15 x 10 inches (380 x 380 x 250 mm)

Precision:

+/- 0.004” or +/- 0.001” per inch, whichever is greater