Think It.

Prototype It.

Market It. Go.

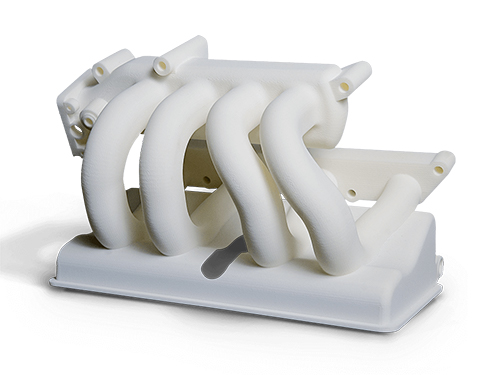

Intek Plastics doesn’t just push the limits — we shape them. Our plastic additive manufacturing technologies let you create real, testable prototype parts, allowing you to see exactly how your concept performs in R&D builds.

No guesswork, no close enough simulations — just actual plastic parts providing real-world insights, faster testing and smarter decisions. Our rapid plastic prototyping services, powered by cutting-edge additive manufacturing, make it easier than ever to bring your ideas to life — quickly, precisely and repeatably. With fast design iterations, consistent part accuracy and rapid speed to market, we help you stay ahead of the competition.

Ask

Why Prototype with Intek?

Whether you need proof-of-concept, a functional show model or on-demand low-volume production, we provide tailor-made solutions for your project. Plus, we bring decades of experience to your project. Our streamlined process reduces development cycles, helping you refine your design quickly and efficiently while minimizing costs.

Rapid Prototyping Capabilities

- Additive Manufacturing: For complex geometries

- 3D Printing: High-quality with fast turnaround

- Cast Urethane for Injection-Molded Quality: Production-grade, low-volume runs, cost-effective

- Fast Design Iterations: Accelerate development

- Consistent, Repeatable: Production-level precision

- Large-Format SLA and SLS: One of the largest build envelopes available

- FAIRs and PPAPs: Documentation to support validation and approval

- Functional Show Models: Presentation-ready

- Multiple Finishing Levels: Basic to refined surfaces

- Custom Coatings: Clear, metallic, epoxy and additional options

- Insert and Decorative Features: Elevate fit, function and appearance

- Speed to Market: Accelerated production

additive manufacturing processes

Stratasys Fortus 400mc

Fused Deposition Modeling (FDM)

Description:

FDM builds three-dimensional parts by melting and advancing a fine ribbon of plastic through a computer-controlled extrusion head, producing parts that are ready to use.

Applications:

- Low-volume production of complex end-use parts

- Prototypes for form, fit and function testing

- Prototypes directly constructed in production materials

Build Size:

14 x 16 x 16 inches (406 x 355 x 406 mm)

Precision:

+/- 0.005” or +/- 0.0015” per inch, whichever is greater

Available Materials:

- Accura Xtreme White 200

- Acurra ClearVue

- Accura 25

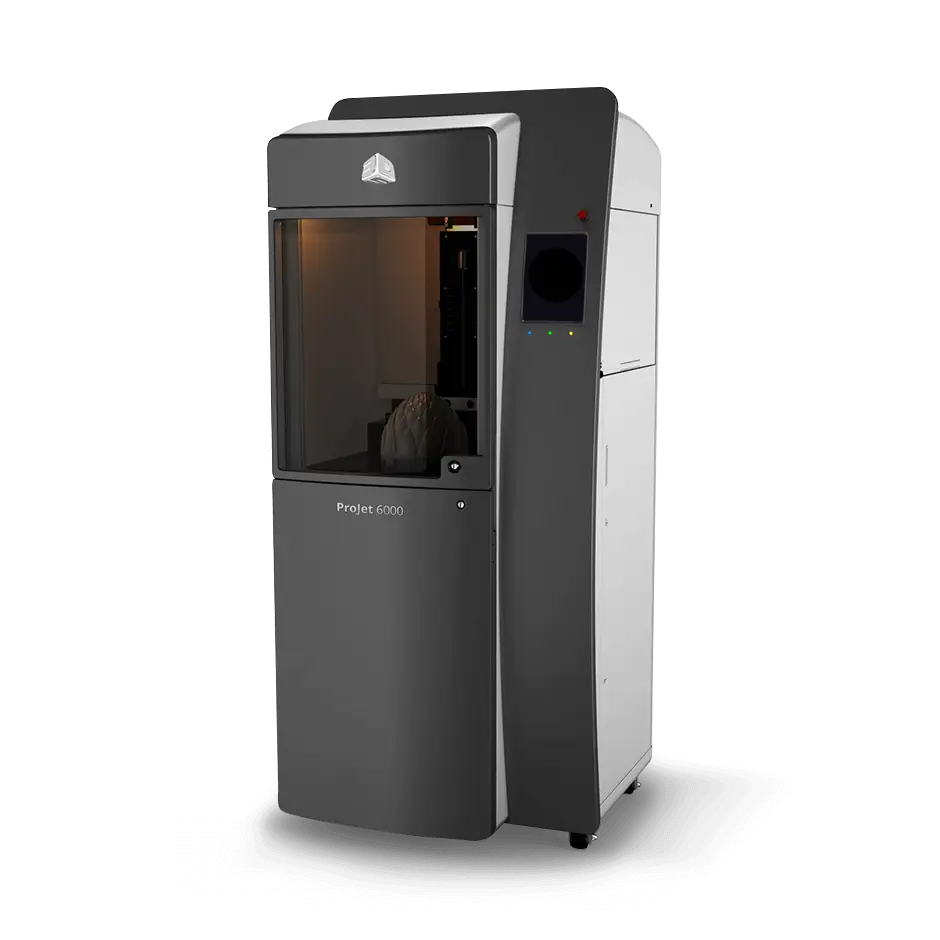

3D Systems ProJet 6000 HD

Stereolithography (SLA)

Description:

Stereolithography is an additive manufacturing process that works by focusing an ultraviolet (UV) laser on to a vat of photopolymer resin.

Applications:

- Design verification

- Complex assemblies

- Mass customization of product (orthodontic, dental)

- Assembly jigs and fixtures

Build Size:

10 x 10 x 10 inches (250 x 250 x 250 mm)

Precision:

+/- 0.004” or +/- 0.001” per inch, whichever is greater

Available Materials:

- Accura Xtreme White 200

- Acurra ClearVue

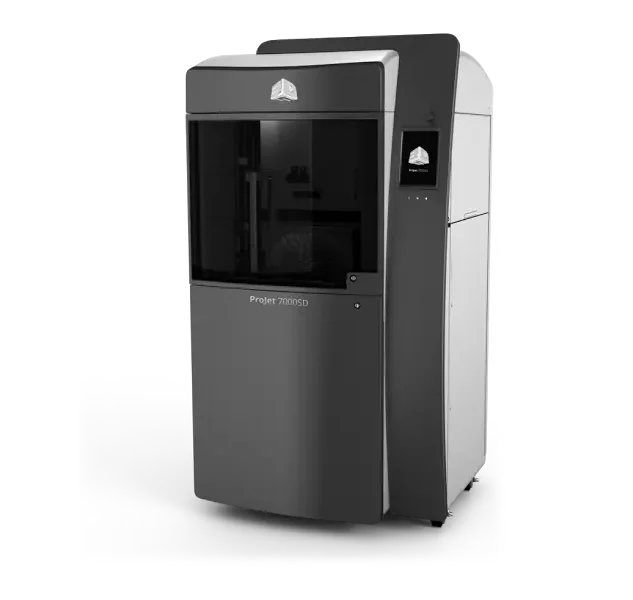

3D Systems ProJet 7000 HD

Stereolithography (SLA)

- Description:

Stereolithography is an additive manufacturing process that works by focusing an ultraviolet (UV) laser on to a vat of photopolymer resin. Same perks and process as the Projet 6000 but with a larger build size.

Applications:

- Design verification

- Complex assemblies

- Mass customization of product (orthodontic, dental)

- Assembly jigs and fixtures

Build Size:

15 x 15 x 10 inches (380 x 380 x 250 mm)

Precision:

+/- 0.004” or +/- 0.001” per inch, whichever is greater

Available Materials:

EOS P730

Selective Laser Sintering (SLS)

Description:

The EOS P730 is a high-productivity plastic laser-sintering system engineered for rapid, precise manufacturing of parts, prototypes and casting patterns. Its dual-laser technology and large build volume enable efficient production of both small batches and large, complex geometries.

Applications:

- Small-run production of fully functional plastic components

- Rapid manufacturing of large, complex prototypes

- Production of investment-casting and vacuum-casting patterns

- High-performance parts for automotive, medical and aerospace

Build Size:

23.9 × 13 × 19.3 inches (607 × 330 × 491 mm)

Precision:

High dimensional accuracy and fine feature resolution

Sinterstation 2500 Plus (SLS)

Selective Laser Sintering (SLS)

Description:

Industrial selective laser sintering machine for functional nylon and composite parts, rapid tooling inserts, and short-run production in automotive, aerospace, medical models, and general engineering applications.

Build Size:

15 × 13 × 18 inches (80 × 330 × 450–460 mm)

Precision:

± 0.004–0.008 inches (f ± 0.1–0.2 mm)

Available Materials:

plastic additive manufacturing materials

Accura ClearVue (SLA)

TRANSPARENT, POLYCARBONATE-LIKE / BIO-COMPATIBLE / DENTAL

Your complete manufacturing partner

Speed and functionality matter. Whatever your project demands, we have in-house technology and expertise to make it happen. Your next breakthrough is just a print away. Let’s prototype the future. Request a quote today.

You get a single, reliable partner who understands your business — not just your parts.

Mission-ready collaboration

We know every component plays a role in a larger mission. That’s why our team works closely with yours to refine part designs for manufacturability — reducing cycle time, minimizing waste and improving overall performance.

From your first prototype to full production, you can expect transparent communication, reliable quality and components that meet your strictest specifications.